What is a Materials Management Plan?

A Materials Management Plan (MMP) can allow the re-use of contaminated or uncontaminated soil, Made Ground and other material in earthworks without the requirement to go through the lengthy and costly process of obtaining an environmental permit.

Arisings generated by site levelling, foundation and basement excavations, road construction and utility service trenches can result in thousands of tonnes of surplus material being generated. In the case of brownfield projects, the off-site disposal of these surplus materials can be a significant cost item, as well as a non-sustainable option, and may impact a projects viability.

This Made Ground material may be considered as waste by the definition set out in the Waste Framework Directive (WFD) Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain directives (2008) meaning it must be handled in line with waste duty of care requirements and cannot legally be used again unless an environmental permit is issued, which can take several months and incur significant application costs.

The CL:AIRE Definition of Waste: Development Industry Code of Practice Version 2 (DoWCoP) (2011) was developed to provide a simplified process to enable the re-use of site-won materials (‘waste’ and non-waste), either on the site of origin, or on another nominated site (movement between sites) without the need for an Environmental Permit.

The CL:AIRE DoWCoP sets out four main principles for the use of materials as non-waste. The Materials Management Plan must contain sufficient information to demonstrate these requirements are met.

- Protection of Human Health and the Environment

Adequate assessment must be undertaken, and where necessary, protection or remediation measures must be specified. Any material that presents unacceptable risk of pollution of the environment or harm to human health it is likely to be classed as a waste, although it may be possible to update the design or treat the material (see point 2).

- Suitable for use

The material must be suitable for the intended use, particularly in terms of its chemical and geotechnical properties. Excavated materials that are suitable for use without requiring treatment are unlikely to be classed as a waste. Material requiring treatment, such as to alter chemical or physical/geotechnical properties will be classed as a waste, but once treated and suitable for use, will no longer be considered waste under an approved MMP.

- Certainty of Use

It must be demonstrated that the materials will actually be used and that the use is not just a probability, but a certainty. The DoWCoP requires this is established at the outset, meaning any material excavated and stockpiled with no pre-defined destination or use will become a waste.

- Quantity of Material Required

Materials should only be used in the quantities necessary for that use, and no more. The use of an excessive amount of material will indicate that it is being disposed of and is waste.

Is an MMP a legal requirement?

The Code of Practice (MMP) is voluntary and applies to England and Wales only. It is possible to demonstrate a material is not a waste outside of this CoP, or to allow re-use of ‘waste materials’ through specific Environmental Permits and agreement with the Environment Agency (EA).

The re-use of surplus soils without an Environmental Permit, Waste Exemption or MMP would be classed as an unauthorised deposit of waste (landfilling) which has legal ramifications and can result in HM Treasury applying landfill tax to the deposited material at the maximum rate.

Requirements on construction sites

An MMP is required if you intend to re-use brownfield soil arisings on your site, or if you intend to bring in clean greenfield soils from another development site.

In accordance with Chapter 1, Article 2 of the Waste Framework Directive article 2(c) states “uncontaminated soil and other naturally occurring material excavated in the course of construction activities where it is certain that the material will be used for the purposes of construction in its natural state on the site from which it was excavated” is exempt from the Waste Framework Directive, and therefore is not classed as a waste.

It will be prudent for sites meeting the above criteria to demonstrate that each criteria has been met, and this can be completed in the form of a written letter addressing each point.

When a client wants to progress with an MMP, it needs to be considered early on in the development scheme and needs to be in place and fully authorised by CL:AIRE BEFORE the excavation and stockpiling of material commences.

An MMP cannot be applied for retrospectively and so any arisings generated prior to an MMP being accepted by CL:AIRE, that are not covered by an existing Waste Exemption or Environmental Permit, will be classed as a waste and must be handled in line with waste duty of care requirements.

Managing soils on-site

Once the MMP is in place, it is important to ensure the soil re-use on-site is correctly managed and recorded.

Regardless of the complexity of your soil re-use, the principles of managing the soils remains the same.

- Plan

As well as having an MMP in place to demonstrate that soils are suitable to be re-used on-site, it is important to also have a plan on how soils will be tracked.

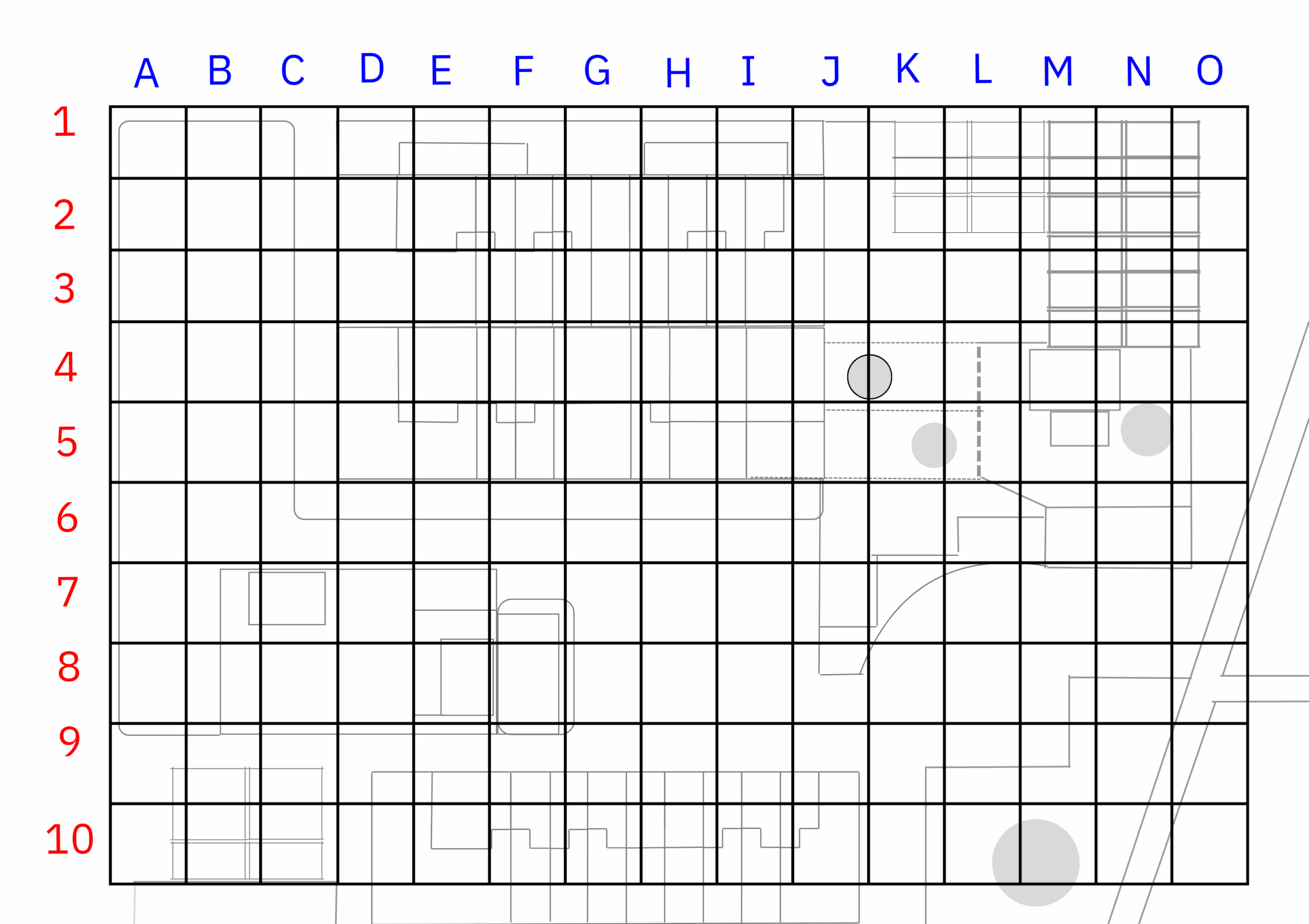

One of the most effective methods of tracking soils is to implement a grid-based system across the site. The grid squares can be as large or small as they need to be depending on the complexity of your site.

For example, if it is really important that soils from 1 corner of the site are only re-used in another small area, it would be better to have smaller grid squares. Whereas if you are only re-using clean materials, and they can be used anywhere on the site, it would be practical to have larger grid squares that represented close to the amount of soils that could be moved per day.

Once you have your grid system decided, you will also need to set up a tracking form to record where materials have arisen from, where they are stockpiled, and where they end up. You can also use this form to record any required testing, import tickets and disposal tickets. This form should be included as part of the MMP application.

- Track

The purpose of the tracking form is to clearly demonstrate where materials have come from, and where they have been placed.

To ensure soils are tracked the whole way through a project, it is key to decide who is going to be responsible for completing the tracking form.

- Drone surveys/Photographs

Using Drone surveys on-site is becoming more and more popular and is a great way of recording what is happening on-site at a given time. When you compare weekly drone photographs of the site, it is easy to see how things have evolved over time. You can use these images to document stockpiles and soil re-use, by annotating them and linking them back to the tracking form.

Recording movements on-site does not have to be as high-tech as using a drone though. The client might have weekly site meetings where they print out a large drawing of the site and draw on where the stockpiles are, what areas are completed, where soils are due to be cut etc. This method is just as effective.

The key with whatever method of tracking you use, is that it needs to be simple, and a small addition to the works the developers are already doing. It is very likely that they are already recording the information needed for managing soil reuse under an MMP.

- Audit

Throughout the soil movement phase of works, it can be helpful to have a 3rd party (eg the person preparing the verification report, but not completing the records) review the records to advise on the information that is being recorded, and to also offer guidance and advice of any problems that may have arisen.

It can be helpful to start the process with a pre-start meeting to discuss the requirements with all parties who will be involved on-site, and come up with the most appropriate tracking system for the site.

Verification & Reporting

Once all the soil movements are complete, you will need to “close out” the MMP with CL:AIRE, which can only be done by submitting a Verification Report.

The CL:AIRE DoWCoP sets out the following will be needed within a Verification Report:

- Appropriate site plans;

- Experience and qualifications of the person preparing the report in relation to the specific project;

- Description of the project;

- Description of how the use of materials links with the Remediation Strategy or Design Statement (which should be set out in the agreed MMP already);

- Reference to site investigation data if applicable (which should be set out in the agreed MMP already);

- Reference to risk assessments (including qualitative risk assessments) (which should be set out in the agreed MMP already);

- Reference to the MMP and associated tracking system, including alterations made and why;

- Suitable for use criteria;

- Treatment records (if applicable);

- Laboratory analysis (if applicable);

- Reference to waste transfer documentation, including return loads (if applicable);

- Signed delivery tickets (if applicable);

- Record of contingency arrangement(s) that had to be implemented;

- Record of quantity of materials used (this can be calculated using a pre-start and post completion topographic survey); and

- Copies of signed Declaration(s) by Qualified Person(s).

If you do not submit a Verification Report for your MMP, the project could be considered “non-Compliant” and the imported/excavated/reused material could potentially be considered as an illegal deposit. CL:AIRE may share such data with the EA / NRW and HMRC.

References

- Waste Framework Directive (2008) Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain directives

- CL:AIRE (2011) Definition of Waste: Development Industry Code of Practice Version 2

Article by Olivia Maxwell (Principal Geo-Environmental Consultant at Omnia Consulting)