Balazs Rigler of Fugro discusses the group’s efforts to improve the efficiency and accuracy of hydrological analyses for nearshore and onshore foundation engineering in soft geology.

The hydrological properties of sandy, chalk or clay geology are of interest to designers of foundations, tunnels and other underground structures. Without a robust understanding of porosity and permeability it is not possible to fully predict soil behaviour under different loading and groundwater regimes and it is harder to determine depth of weathering and risk of dissolution in chalk. But by the very nature of their diffusive relationship with water, these ground types present a range of physical and interpretative challenges in deriving accurate data on porosity, permeability and associated characteristics.

To date, engineers requiring porosity and permeability data have mostly relied on outputs from core analyses and packer testing techniques, which are limited by factors including core loss, low sample density, feasibility and cost. No single method has been effective in isolation, progress rates are slow and investigation of soft ground such as clays, is particularly problematic.

To address these challenges, Fugro is making significant progress with a downhole technique more usually associated with mining, and offshore oil and gas prospecting – Nuclear Magnetic Resonance (NMR).

A first important point to make is that NMR does not employ any radioactive source material, as its name might seem to suggest. Using the same principle applied in Magnetic Resonance Imaging (MRI) for medical scanning, NMR logging analyses the spin of hydrogen nuclei under the influence of magnetic forces.

Innovative

Though well-established in the oil and gas and mining sectors, NMR’s application for engineering and land geotechnical projects is quite innovative. Fugro has implemented the technology as part of its borehole geophysics offering because it can provide valuable hydrogeological insight for near-surface site characterisation projects.

The NMR technique effectively logs both porosity and permeability and can distinguish between mobile, capillary-bound and clay-bound water. It is effective in air, water or drilling mud and is less sensitive to variations in borehole conditions than other techniques.

The technique can be used in uncased or plastic/fibreglass cased holes (minimum = ~75 mm) even when grouted, eliminating the risk of borehole collapse, which often prevents the deployment of methods reliant on a radioactive source, such as neutron porosity.

Crucially, the NMR technique samples the ground formation away from the borehole wall and, unlike conventional downhole methods, is unaffected by borehole fluid, borehole wall geometry, mud cake or drilling induced disturbance of the near borehole formation.

NMR is thus well-suited to a wide variety of ground conditions including soft superficial sediments, clays, carbonates (limestone and chalk), sandstone and other sedimentary rocks. The method can provide unique information in certain geologies where parameters derived from other downhole techniques could be fundamentally flawed due to borehole conditions, complexity of data processing and (sometimes empirical) interpretational procedures.

Though they are of most interest in terms of hydrological properties, sandy soils can be the most difficult to core and are often imperfectly recovered, hence NMR provides an immediate fix for this type of problem.

Lithology

In addition, parameters derived from NMR measurements are independent of variations in lithology and do not rely upon empirical or lithology specific ‘corrections’. This is an important advantage for designers needing accurate, robust and reliable data on the saturated water volume and hydraulic properties of the ground for the foundations of river bridges, tunnels and other structures.

Using NMR data, formation porosity variations can be accurately measured and there is great potential to estimate or derive hydraulic permeability to provide information. Porosity and permeability as engineering parameters are typically provided as a continuous wireline geophysical log, thus avoiding the need for guesswork or interpolation in the event of limited core recovery or low packer test sample density.

Clay volume of formation can also be determined with a high level of confidence with some support from natural gamma log data.

NMR measurements and deliverables can be summarised as:

■ Calculation of total water content

■ Porosity (if water saturated) independent of rock matrix

■ Pore space distribution

■ Distribution of clay bound/capillary bound/mobile water

■ Permeability/hydraulic conductivity

■ Moisture content in the unsaturated zone – dry density can be derived with support from gamma-gamma density logging

Transition

NMR’s transition to onshore geotechnical applications and smaller diameter boreholes has only been possible with the recent introduction of appropriate slim hole tools.

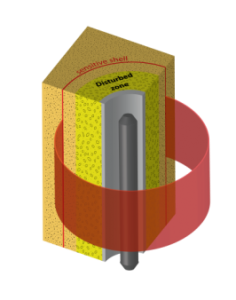

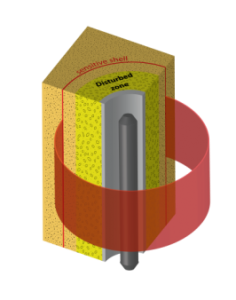

The downhole sensor characteristics can be optimised based upon borehole diameter and geology to investigate concentric shells around the borehole; this allows discrete evaluation of the ground outside the zone disturbed by drilling. The specific measured zone lies within a 200 mm to 400 mm diameter of the sensitive shell (see Fig 2).

NMR logging works in continuous or stationary mode and, unless very large diameter wash-outs are present, borehole conditions have no effect on the measurements. The presence of such wash-outs can easily be determined by standard caliper downhole measurements.

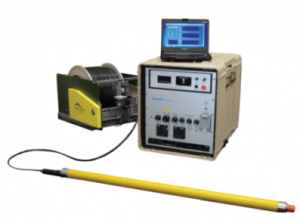

The set-up is relatively low cost and portable, with a very wide range of probe sizes. The typical tool diameter for slim hole operations is 60 mm and maximum logging depth is ~1500 metres.

With the plastic/fibreglass sleeve ensuring data can be successfully gathered from a borehole without risk of collapse, the technique is saving time and money for over-water work, particularly where extra boreholes and jack-up platform/vessel time may be needed to use conventional techniques.

NMR is the only method which provides direct and lithology-independent information about water, moisture content and permeability as a continuous log.

The lateral investigation depth of the method is based on the well-defined cylinder about the borehole, with a minimum and maximum diameter from the borehole axis as a function of the magnet and coil array geometry and frequency of B1. High frequency tools have better signal-to-noise ratios but are sensitive closer to the tool, while low frequency tools yield data further away from the borehole. Thus, tool selection can be designed in a way that the readings are not influenced by the fluid in the borehole, the mudcake or the strongly altered, disturbed formation close to the borehole.

This greatly facilitates the collection of guaranteed porosity data readings along the full length of the borehole, even in unstable geology.

Permeability and hydraulic data

NMR also provides time and cost advantages when it comes to capturing hydraulic permeability data.

There is a limit to the retrieval of permeability data using other types of discrete tests, often leading to the additional need for comparatively expensive pumping tests.

With conventional methods, unless transit is estimated, permeability will require additional in situ logging based on packer testing and/or injection testing which involves complicated hardware and heavy equipment. This type of test only takes point measurements, while NMR provides a continuous log the full length of the borehole. In order to capture permeability and hydraulic transit data, several distinct surveys will be necessary involving separate hardware assemblies. Through the use of different size probes and frequencies, NMR logging captures all required data using one set-up, to save time and cost.

Improvement in the accuracy of permeability data is a particular focus of Fugro’s advancements in the use of NMR for civil engineering.

Calculation of porosity is straightforward, derived by separating the water content of the target strata into bound (clay or capillary) and free/mobile water content.

Maximised value

With insightful early planning with the client and designers, value from NMR can be maximised by clever selection of complementary downhole investigation techniques to facilitate measurement of permeability and other required hydrogeological data.

In a recent Fugro project, an NMR approach afforded greater surety of data capture across the target strata (chalk) than would have been possible using traditional (neutron porosity) radioactive source based methods. As well as the clear HSE benefits, the method provided valuable and comprehensive hydrogeological data critical to facilitate a robust characterisation of risk to foundation design within the chalk.

Borehole CCTV or an optical televiewer, for example, are often chosen to assess water inflow into a borehole, and outflow via fractures and joints. As a minimum, both methods need clear water to be effective since image quality suffers in murky water – to achieve this is often a challenging and time consuming operation in soft sedimentary geology.

For a current bridge foundation project, Fugro has used NMR combined with an acoustic televiewer to overcome the problem of ‘milky’ water within the borehole due to chalk geology. Use of a conventional borehole CCTV system would have involved flushing out the cloudy water and leaving the borehole to stand for anything between 24 and 72 hours to achieve the right conditions for optical inspection. This approach would mean taking two or three extra days of jack-up time per borehole and would also increase the risk of borehole collapse and associated requirement for redrilling operations. Both factors would result in a significant increase in cost and time required for the site characterisation programme.

Conclusion

Current advances in downhole NMR are especially exciting for near surface investigations for infrastructure development.

As discussed, the technique is effective whatever the water volume of the ground formation in the saturated zone, or whether its representation is clay bound, capillary bound or mobile water. NMR offers the potential to derive accurate, robust and reliable data on porosity and its relationship with permeability in order to provide information directly related to engineering properties and other important values.

With further work and evaluation, Fugro anticipates it could contribute much to characterise chalk and engineering properties wholly based on porosity, water content, clay content, acoustic and gamma density data.

As well as being of value for foundation design and tunnelling, the NMR method also offers potential for other applications such as water abstraction, flood alleviation schemes, grain size distribution, pit slope stability, open and closed fracture identification, tailings dams, mining and environmental investigations.

But technical progress like this, enhancing the site investigation (SI) industry’s capability to clarify risk for developers with benefits for programme efficiency, needs early collaboration to fully realise the benefits.

The expansion and upgrade of modern infrastructure, from city to coast, does not enjoy geographical and geological freedom; invariably its location will interact with less than ideal ground, complicated by historical use or adjacent development. Yet insufficient SI continues to rank as a major contributing factor to civil engineering and construction project overruns.

Risk and cost management in infrastructure development relies fundamentally on a robust, integrated and well planned SI and its power to create a fully evolved ground model specific to the development site. Only with this can ground risk be confidently characterised, taking full advantage of advanced and cutting edge methods such as NMR, in order to safely and successfully realise vital infrastructure development in challenging places.

Balazs Rigler is a wireline services manager at Fugro. This article was featured in the May/June issue of the AGS Magazine, which can be viewed here.

Images:

Fig 1: An example of logging equipment for NMR (Vista Clara)

Fig 2: Schematic drawing of the sensitivity zone (red shell) of a NMR sonde. [Walsh 2013]

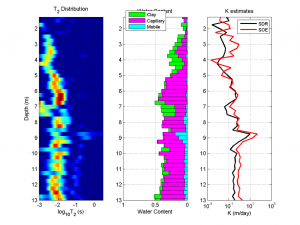

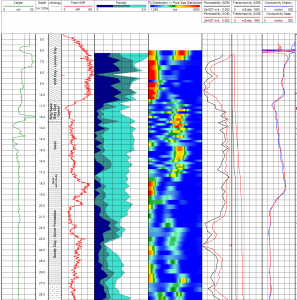

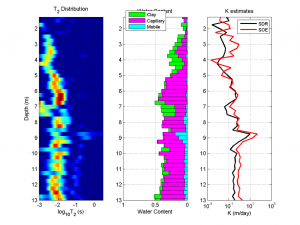

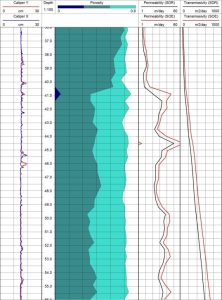

Fig 3. Example NMR dataset with thin sandy strings in low permeability material

Data from NMR logging in an environment dominated by silts and clayey silts, but with some thin sand stringers. Note the large detected increase in the amount of mobile (large pore) water at ~9 metres. Below 9 metres there is a small but substantial fraction of mobile water which likely reflects the presence of very thin sand lens of the order of cm.

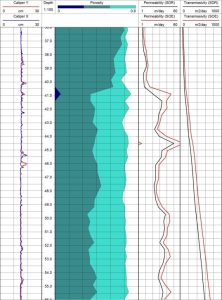

Fig 4. Example of NMR data from chalk (in the UK)

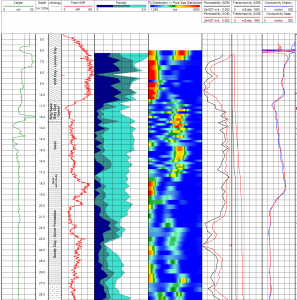

Fig 5 Example NMR data from London Clay and soft sediments in London

Data were acquired in East London and composite logs were made to compare results with spectral gamma and formation electrical conductivity logs. Logs demonstrate strong correlation and significant anomalies in gamma, water content, porosity and pore size distribution logs at shallow interval in the London Clay.